2022-05-23

(1)

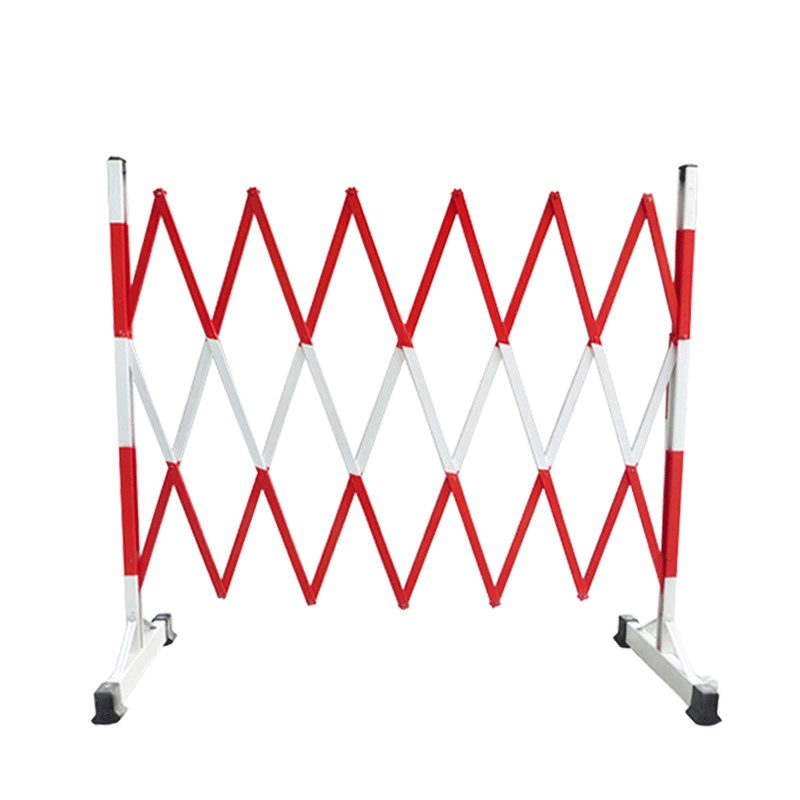

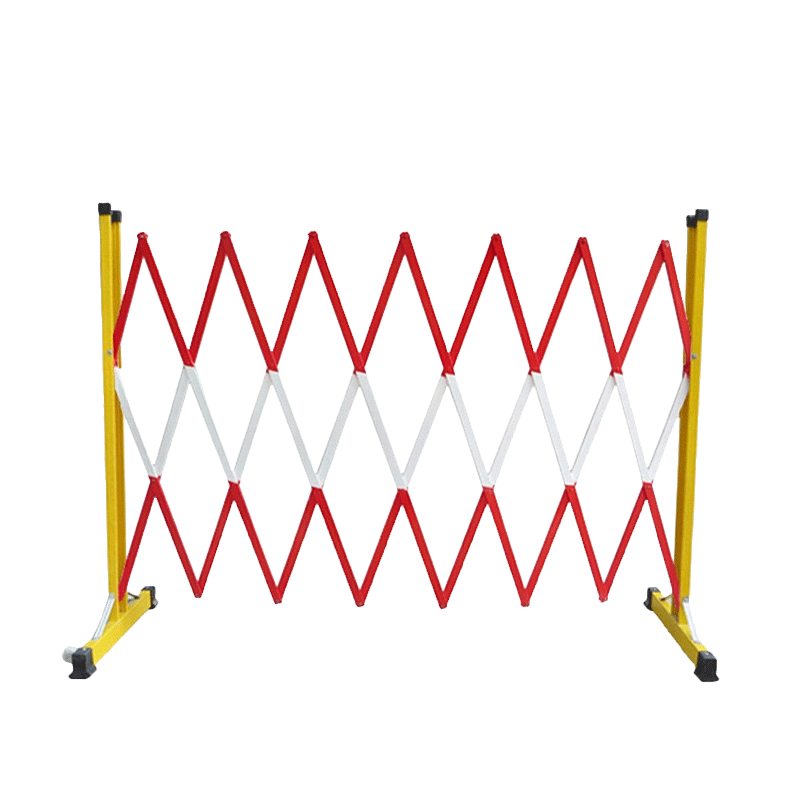

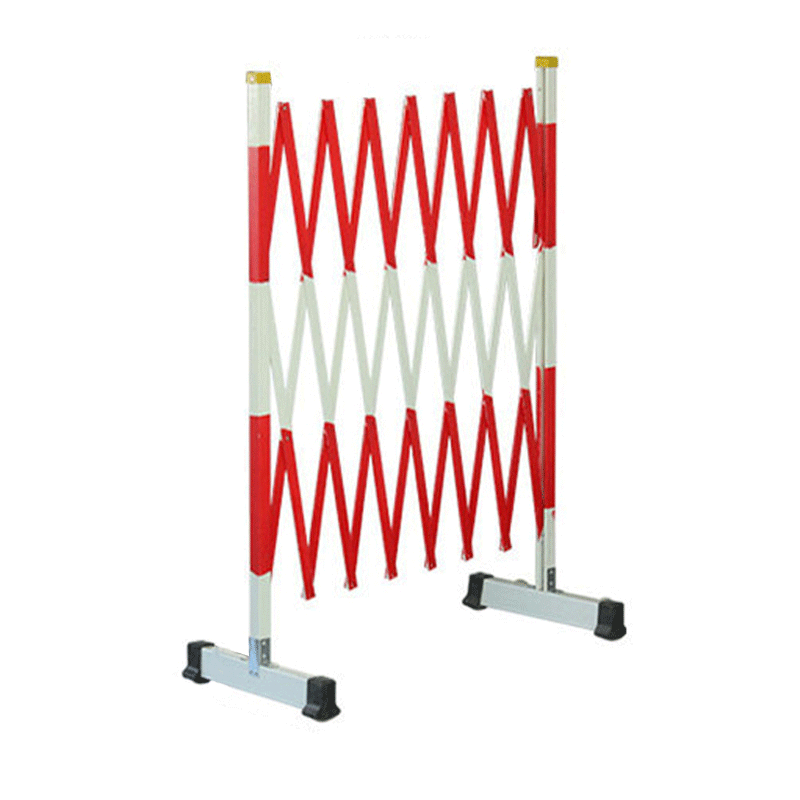

Details determine quality and safety than sales of stainless steel telescopic fence factory direct sales: easy connection, fine craftsmanship, sturdy and durable, easy to expand and retract, eye-catching warning. Our advantages are insulating protective caps, which can be connected with safety buckles, red and white, high-quality stainless steel, can be connected to stainless steel columns, fixed screw connections, non-slip and wear-resistant shading. Details show screw fixation: all the willows are made of alloy material, which is extremely strong, and at the same time has the properties of corrosion resistance and no rust. High-quality stainless steel material Stainless steel 201 material, which can cope with the corrosion of the fence in rainy and snowy weather, and is durable. The simple connection design of the fence adopts the design of the bayonet on the left and the stainless steel clip on the right, which is convenient for the connection of the fence. It is widely used in power supply bureaus and power plants. , safe isolation of roads such as substations, factory workshops, kindergartens, road construction, etc. Sinopec gas station.

Stainless steel telescopic guardrail is a new type of safety warning and maintenance product. It is an improvement and innovation on the basis of the original mesh fence and is a new generation of fence products. It is a product recommended by the power sector. It has the characteristics of good tensile strength, not afraid of wear and tear, not afraid of rain, and anti-aging.

Stainless steel telescopic fences are widely used in banks, stations, hospitals, post offices, theaters, airports, airports, subways, this product is the best choice for guiding routes, and it is also widely used in power distribution maintenance, electrical maintenance, reconstruction construction, transportation, The company sets up cordons and other stopping places, etc.

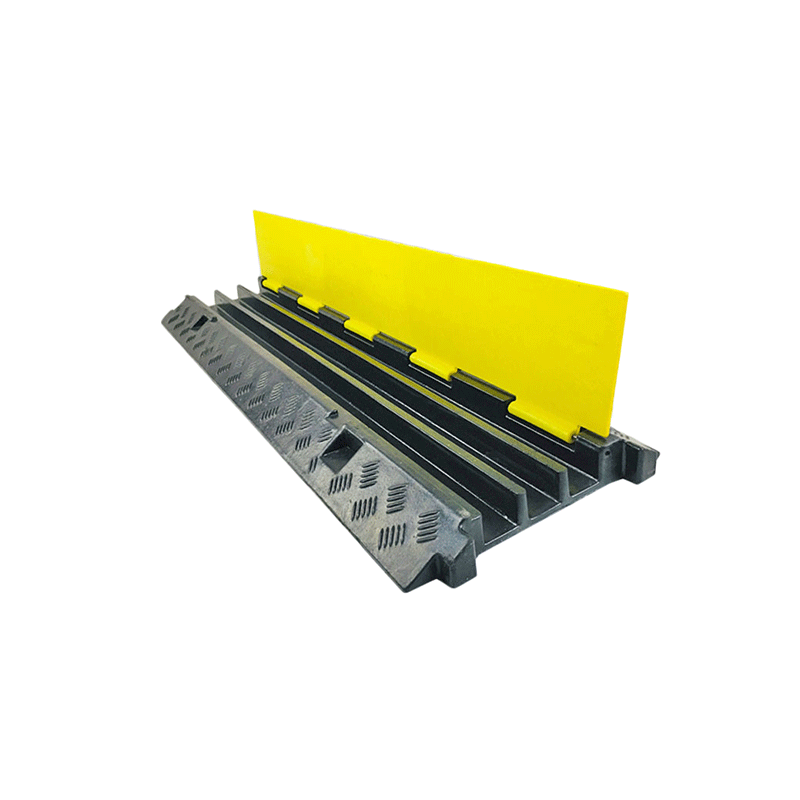

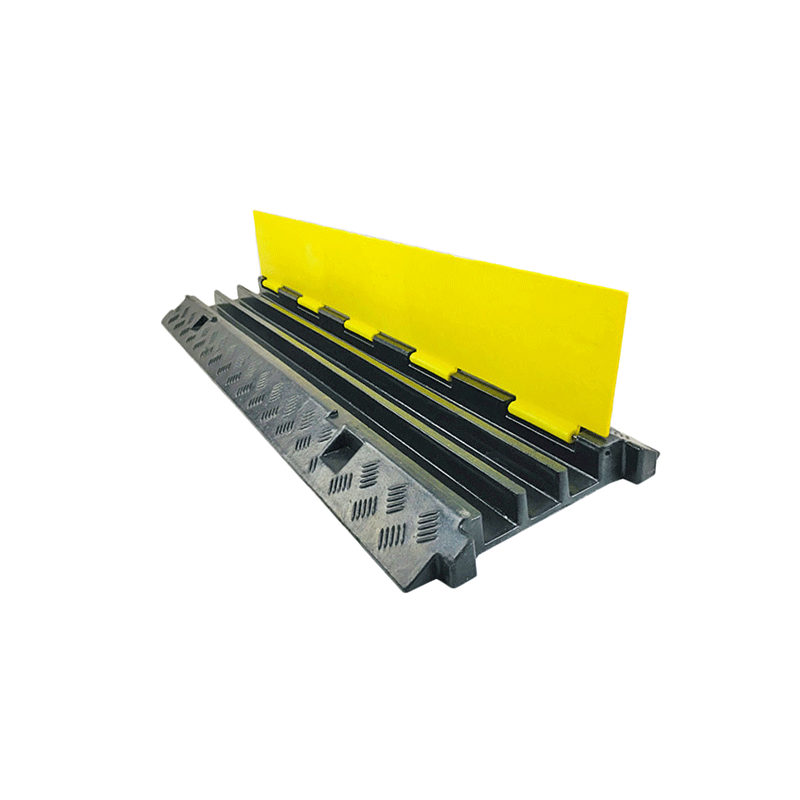

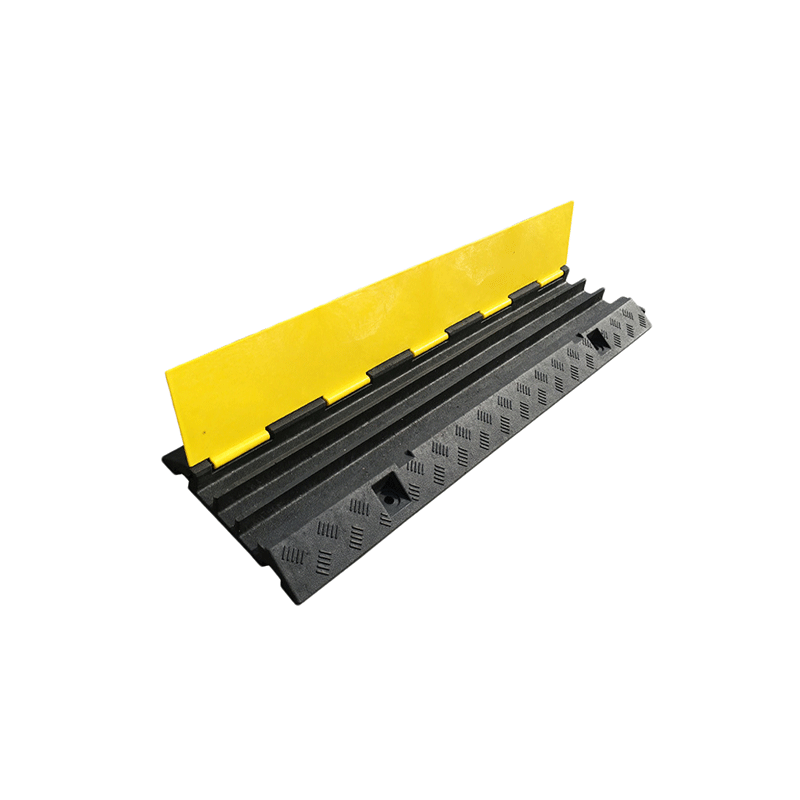

(2)

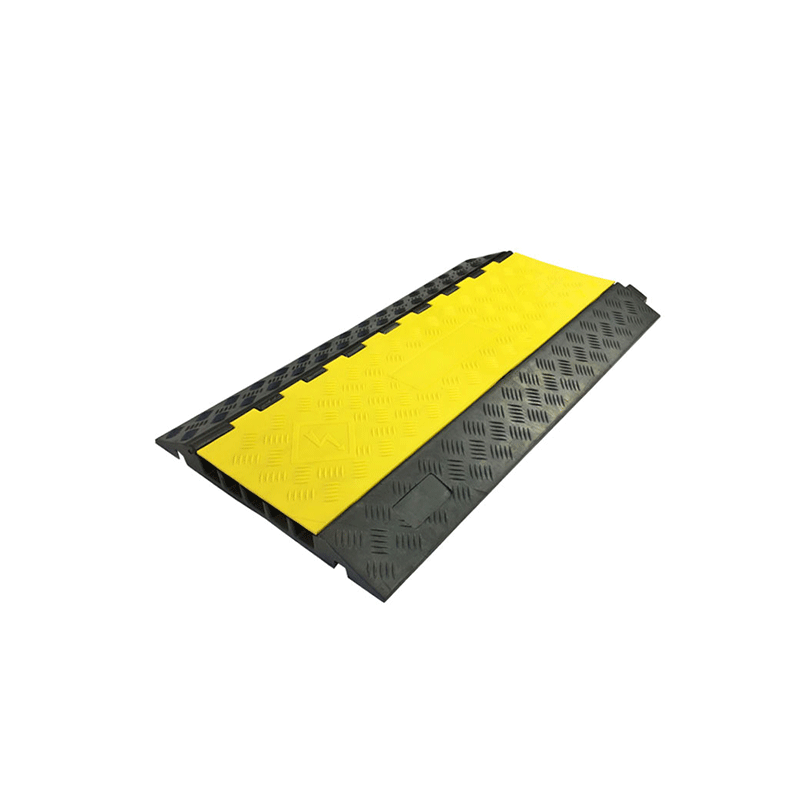

The main raw materials of PVC rubber deceleration groove plate are raw rubber, various compounding agents, and fibers as skeleton materials. The basic production process of PVC rubber deceleration groove plate includes plasticizing, mixing, calendering, extrusion, molding, vulcanization, There are 8 basic processes of testing and packaging. The processing process of rubber is mainly a process of solving the contradiction between plasticity and elasticity. Through various processing methods, the elastic rubber is turned into a plastic plasticized rubber, and various compounding agents are added to make semi-finished products, and then vulcanized to become plastic. The semi-finished product becomes the deceleration belt slot with high elasticity and good physical and mechanical properties.

1. Plasticizing process

Raw rubber mastication is a process in which raw rubber is transformed from a tough elastic state to a soft, easy-to-process plastic state through mechanical stress, heat, oxygen or the addition of certain chemical reagents.

The purpose of plasticizing raw rubber is to reduce its elasticity, increase plasticity, and obtain appropriate fluidity to meet various processing processes such as mixing, sub-derivation, extrusion, molding, vulcanization, glue manufacturing, and sponge rubber manufacturing. requirements.

The PVC rubber deceleration groove plate belongs to natural rubber. When using an open mixer for plasticizing, the temperature of the roller is 30-40℃, and the time is about 15-20min; 3-5min.

2. Mixing process

Mixing refers to the process of uniformly mixing various compounding agents into raw rubber seeds on a rubber mixing machine. The quality of mixing has a decisive influence on the further processing of the compound and the quality of the finished product. Even if the compound with a good formula is not mixed well, the compounding agent will be unevenly dispersed, and the compound plasticity will be too high. Or too low, easy to scorch, frost, etc., so that the processes of calendering, extrusion, gluing and vulcanization cannot be carried out normally, and it will also cause the performance of the product to decline.

The PVC rubber deceleration groove plate adopts the mixing method, which is also the most widely used method in the rubber industry at present.

3. Calendering process

Calendering is a process in which the rubber compound is made into a film on a calender or a semi-finished tape with a skeleton material. It includes operations such as sheet pressing, lamination, molding and textile hanging.

The calendering process of PVC rubber deceleration groove plate generally includes the following steps: preheating and supplying of rubber compound; leading and drying of textile (sometimes dipping)

4. Extrusion process

The extrusion process is to make the rubber material achieve the purpose of extrusion and preliminary modeling through the action of the barrel wall and screw parts of the extruder, and the extrusion process is also an extrusion process.

The main equipment of the extrusion process is the extruder

Scope of application:

1. Stages, hotels, exhibitions, large venues, and sports grounds have car passages in the aisles

2. Places where wiring is required in living quarters, shopping malls, office buildings, and parking lots of government agencies.

3. There are places where vehicles enter and exit the material warehouse, the place where personnel and goods are collected and distributed.

4. There are aisles where forklifts pass back and forth in the factory workshop

The characteristics of PVC rubber deceleration groove plate:

1. Load: 2-10 tons/M2

2. Easy to install and easy to move

3. Good insulation performance, can withstand 2500v voltage, avoid the danger of electric shock and leakage.

4. The appearance is neat and beautiful, and the construction is simple and convenient.

Uses: It is used in the exhibition company of the engineering department and the construction line of the power company to protect the line.

Chengdu Jinhongyuan Industry and Trade Co., Ltd. was established in 2008. After 14 years of development, it has become a large-scale stainless steel and rubber and plastic products enterprise with advanced product R&D and design capabilities and excellent manufacturing capabilities. The factory is located in Chengdu, which is known as the Land of Abundance, 15 kilometers away from the city center, with superior geographical location and convenient transportation. The factory covers an area of 30 acres, with a workshop of 12,000 square meters. It has 17 sets of various types of injection molding machines ranging from 2,000 grams to 30,000 grams and supporting intelligent automation equipment. The company ensures the quality of every product. The factory has ten major categories of products, mainly including: scraper tents, tarpaulins, stainless steel telescopic fences, PVC deceleration trough boards, railway crossing boards, polyethylene films, packaging wrapping films, sanitation trash cans, classified trash cans, cervical vertebrae Massager etc. At the same time, the factory can also undertake bulk purchases, product customization, and processing for domestic and foreign customers. Striving to be a leading domestic and western first-class stainless steel and rubber and plastic products enterprise is our original intention that has not changed for 14 years, and we look forward to working with you.

Contact Person:Qiu Wujun

Email:glenloshi52@gmail.com 207076352@qq.com

06-13

06-13

06-13

06-13

06-13

06-13

06-13

06-13

06-12

06-12